Weapons

Anti-aircraft tracers in the night sky above Kadena Field, Okinawa, Japan, 28 April 1945. US Marine Corps F4U Corsair fighters of VMF-312 in foreground.

Weapons Overview

War fighting requires speed, tactics and weapons if victory is to be achieved. While transports like USS Elmore (APA-42) were not fast ships, they were designated as Attack Transports. They were armed and capable of defending themselves. The weapon systems used were all standard US Navy-issue. These were Elmore's guns:

• 2 x single 5 inch/38 cal. dual purpose gun mounts, one fore and one aft.

• 2 x quad 1.1"/75 caliber ("Chicago piano") gun mounts aft port and starboard, replaced by 2 x twin 40mm AA (Bofors) gun mounts.

• 2 x single 40mm AA (Bofors) gun mounts.

• 18 x single 20mm AA (Oerlikon) gun mounts.

Click on the blue tabs at the top of this page to read about each of Elmore's weapon systems.

USS Elmore and her Bayfield-class sister ships all had 2 single 5 inch/38 cal. dual purpose gun mounts, one fore and one aft.

A Mk 21 5"/38 caliber open pedestal mount in 1942.

Source: Wikipedia

Mark 12, 5"/38 Caliber Gun

The Mark 12 5"/38 caliber gun was mounted on a large number of US Navy ships during the World War II era. The ability to project force while miles at sea has always been a key ingredient to the success of modern warships. Using their 5 inch guns, such ships had the ability to fire a 55 lb. projectile over 9 miles. This, in fact, occurred in supporting U.S. Marine Corp ground troops during the Guadalcanal campaign, fought between 7 August 1942 and 9 February 1943.

The Mark 12 5"/38 caliber gun was a United States naval gun. The gun was installed into Single Purpose and Dual Purpose mounts. On these 5" mounts, Single Purpose (SP) means that the mount was limited to 35° elevation with no provision for AA shell fuze setters, and is designed to fire at surface targets only. Dual Purpose (DP) means that it is designed to be effective against both surface and aircraft targets because it can elevate to 85° and has on mount AA shell fuze setters.

United States naval gun terminology indicates the gun fired a projectile 5 inches (127mm) in diameter, and the barrel was .38 calibers long. The rate of fire for the MK 38 mount was typically 15 rounds per minute. The comparatively high rate of fire for a gun of its caliber earned it an enviable reputation, particularly as an anti-aircraft weapon, a role in which it was commonly employed by United States Navy vessels.

Click to zoom

Among naval historians, the 5"/38 gun is considered the best intermediate-caliber, dual purpose naval gun of World War II, especially as it was usually under the control of the advanced Mark 37 Gun Fire Control System which provided accurate and timely firing solutions against surface and air targets. Even this advanced system required nearly 1000 rounds of ammunition expenditure per aircraft kill. However, the planes were normally killed by shell fragments and not direct hits; barrage fire was used, with many guns firing in the air at the same time. This would result in large walls of shell fragments being put up to take out one or several planes or in anticipation of an unseen plane, this being justifiable as one plane was capable of significant destruction.

The open single pedestal mount was the first 5"/38 cal type installed on navy ships. Since these mounts did not have Upper Handling Rooms [a base ring stand that had an ammunition handling room below the mount], they could be installed on ships without extensive reconstruction. For that reason, they were widely used on amphibious ships, auxiliaries, and merchant ships.

USS Elmore and her Bayfield-class sister ships all had 2 single 5 inch/38 cal. dual purpose gun mounts, one fore and one aft.

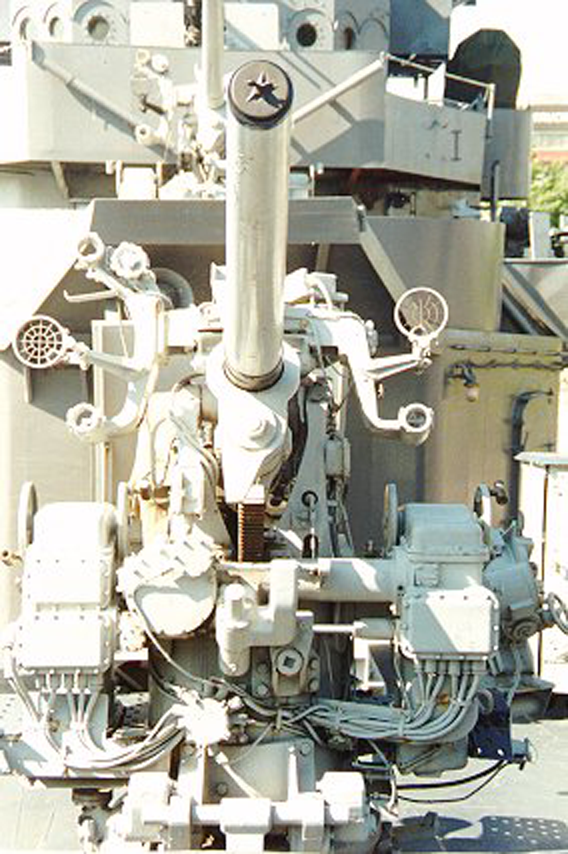

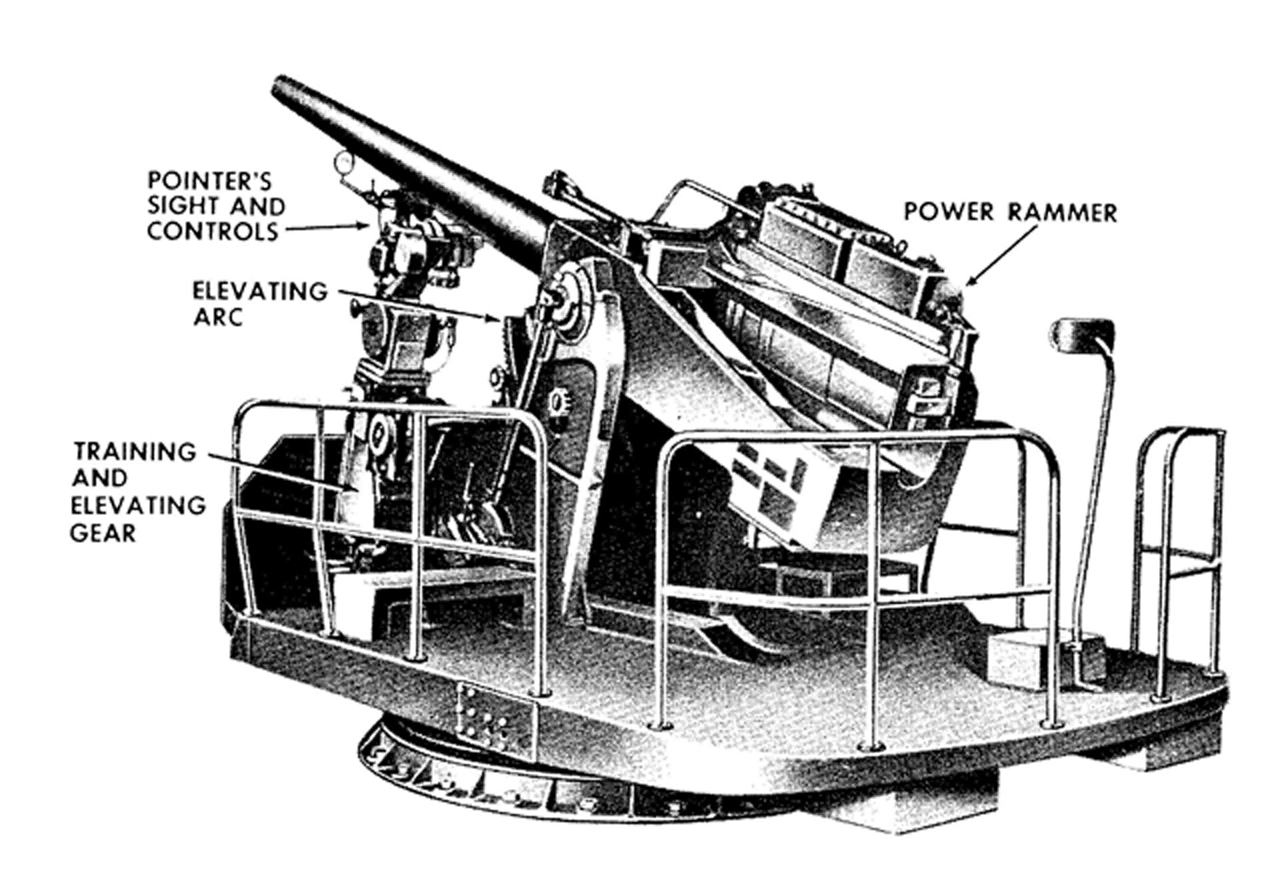

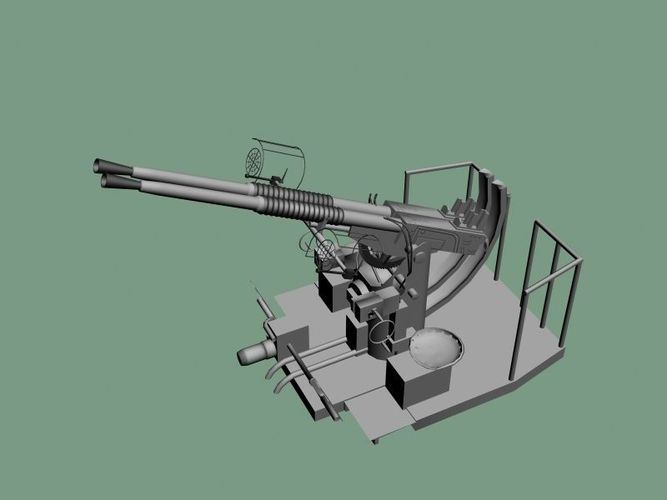

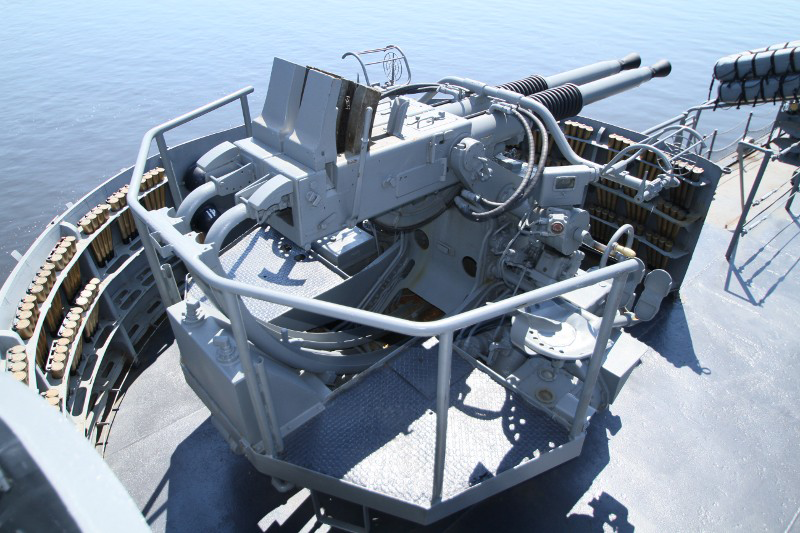

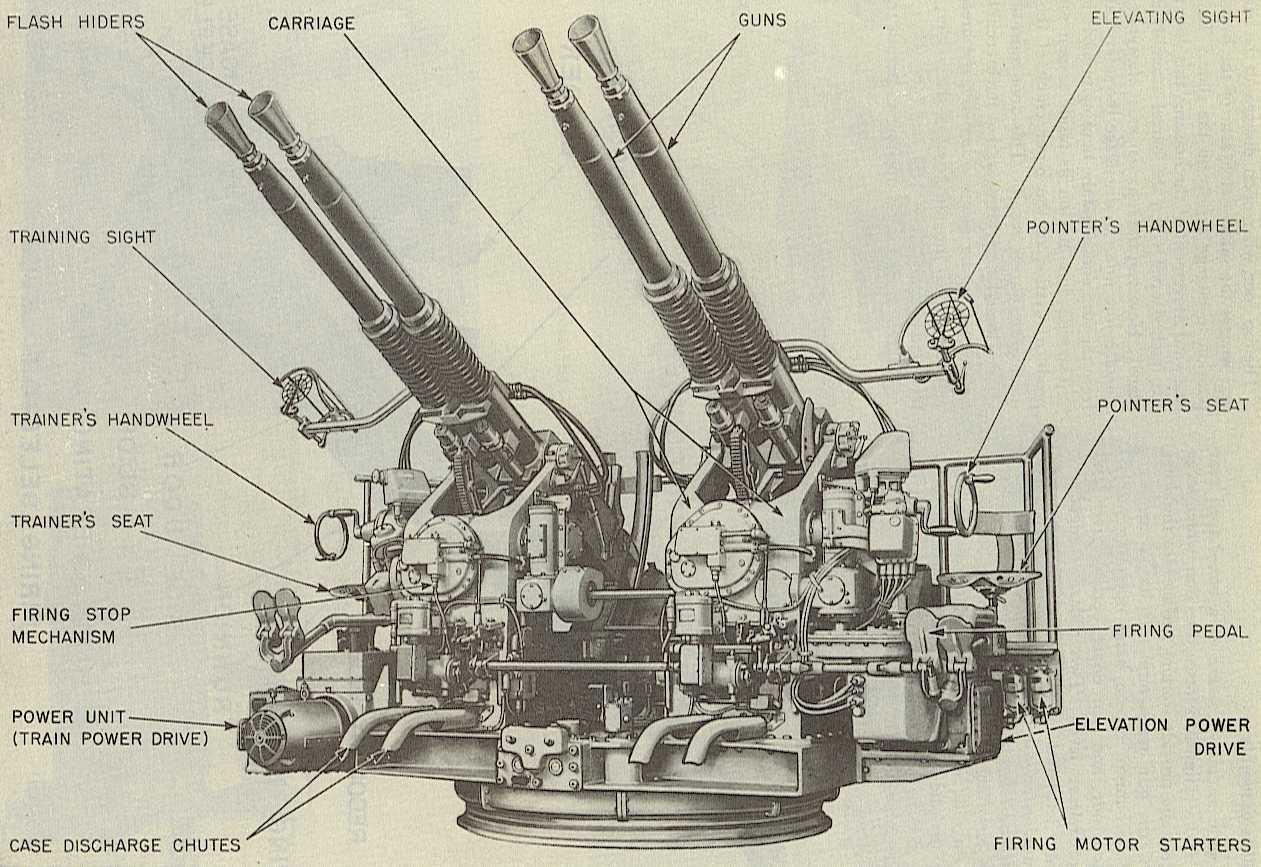

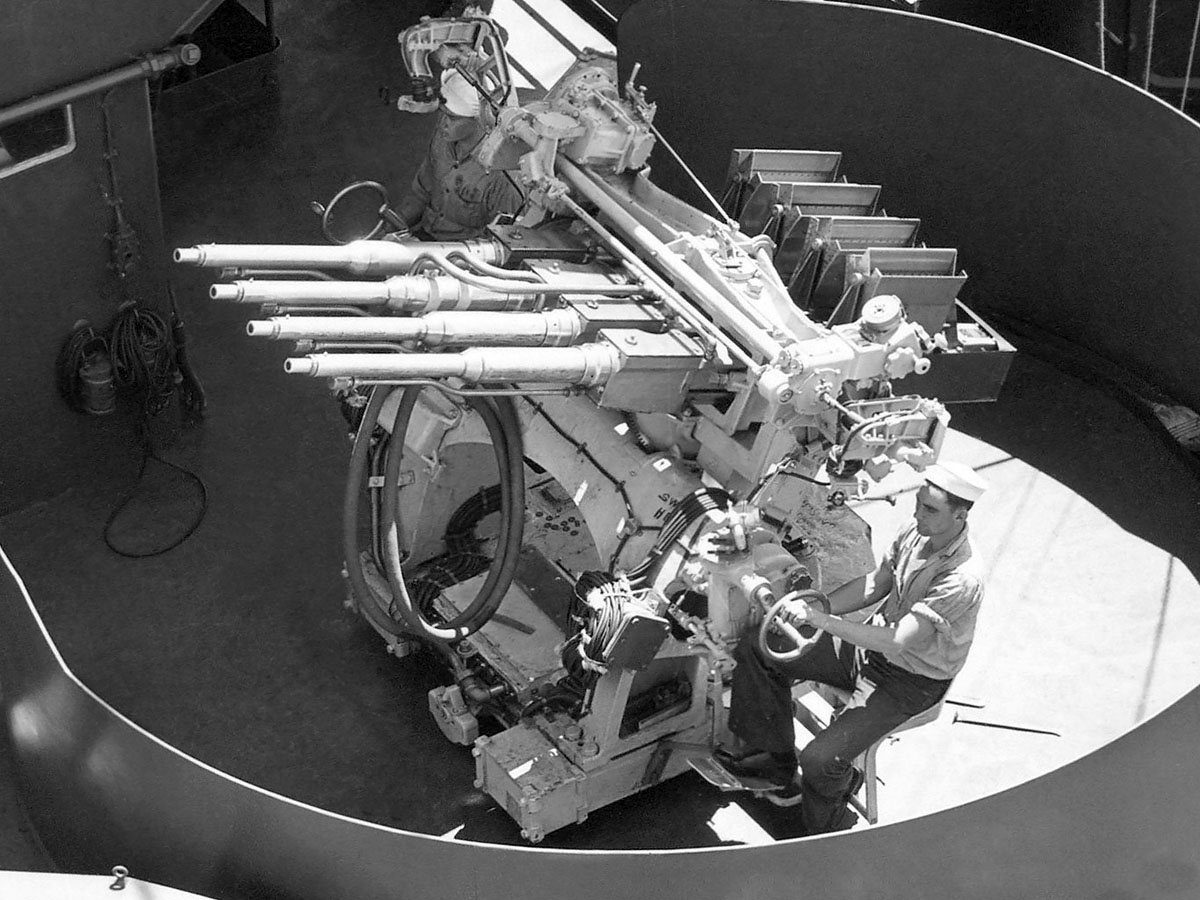

U.S. Navy Mk.I (Dual) Mount

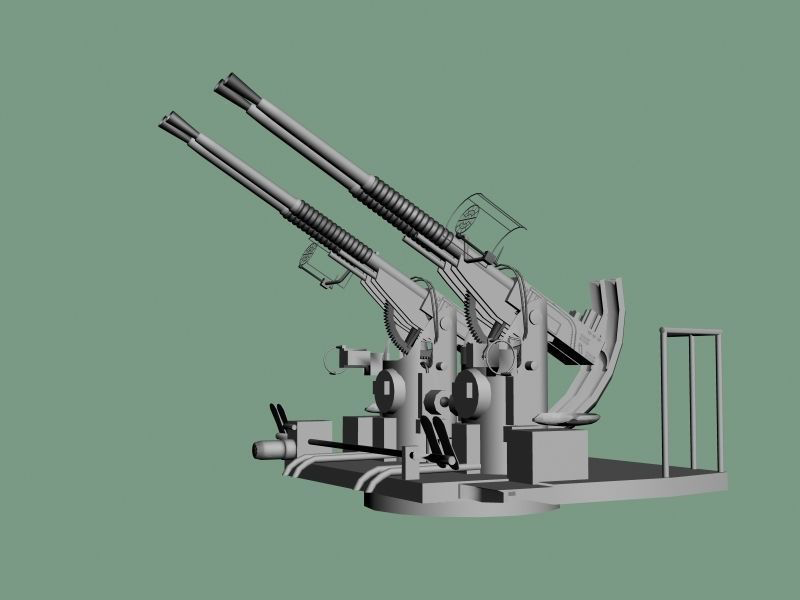

U.S. Navy Mk.II (Quad) Mount

Bofors 40mm Anti-Aircraft Gun

Description

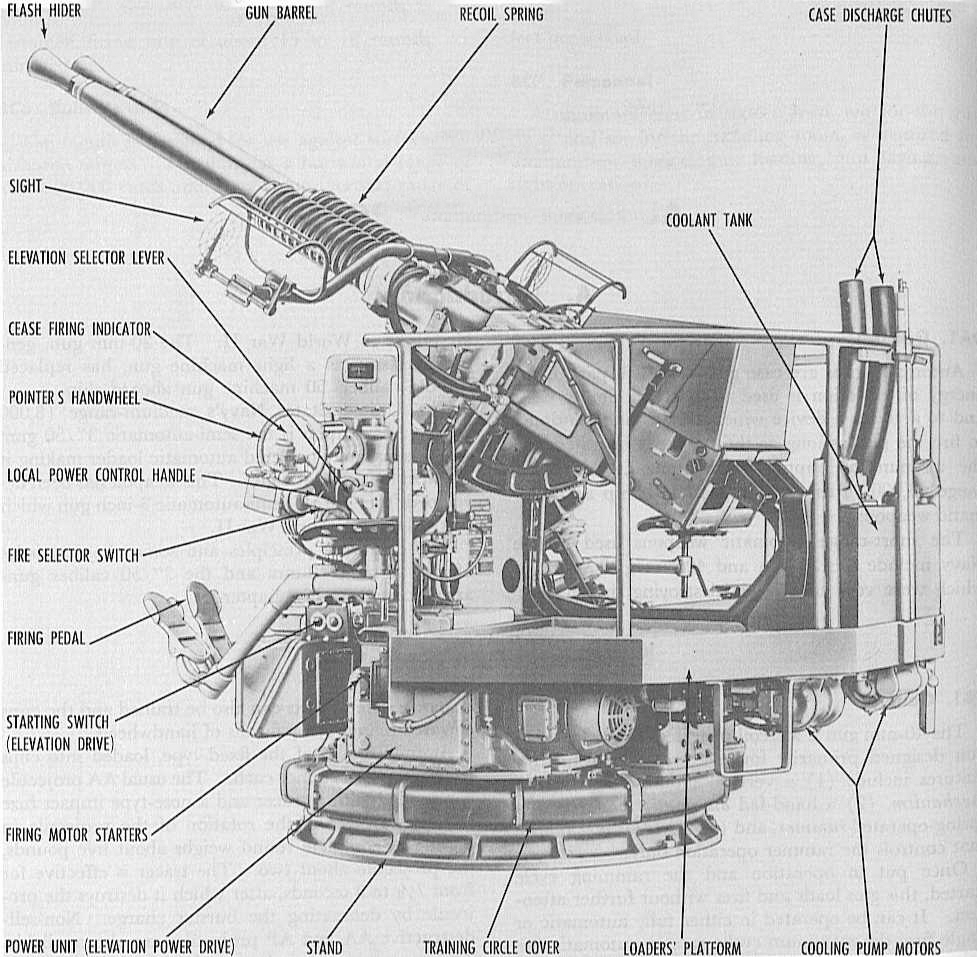

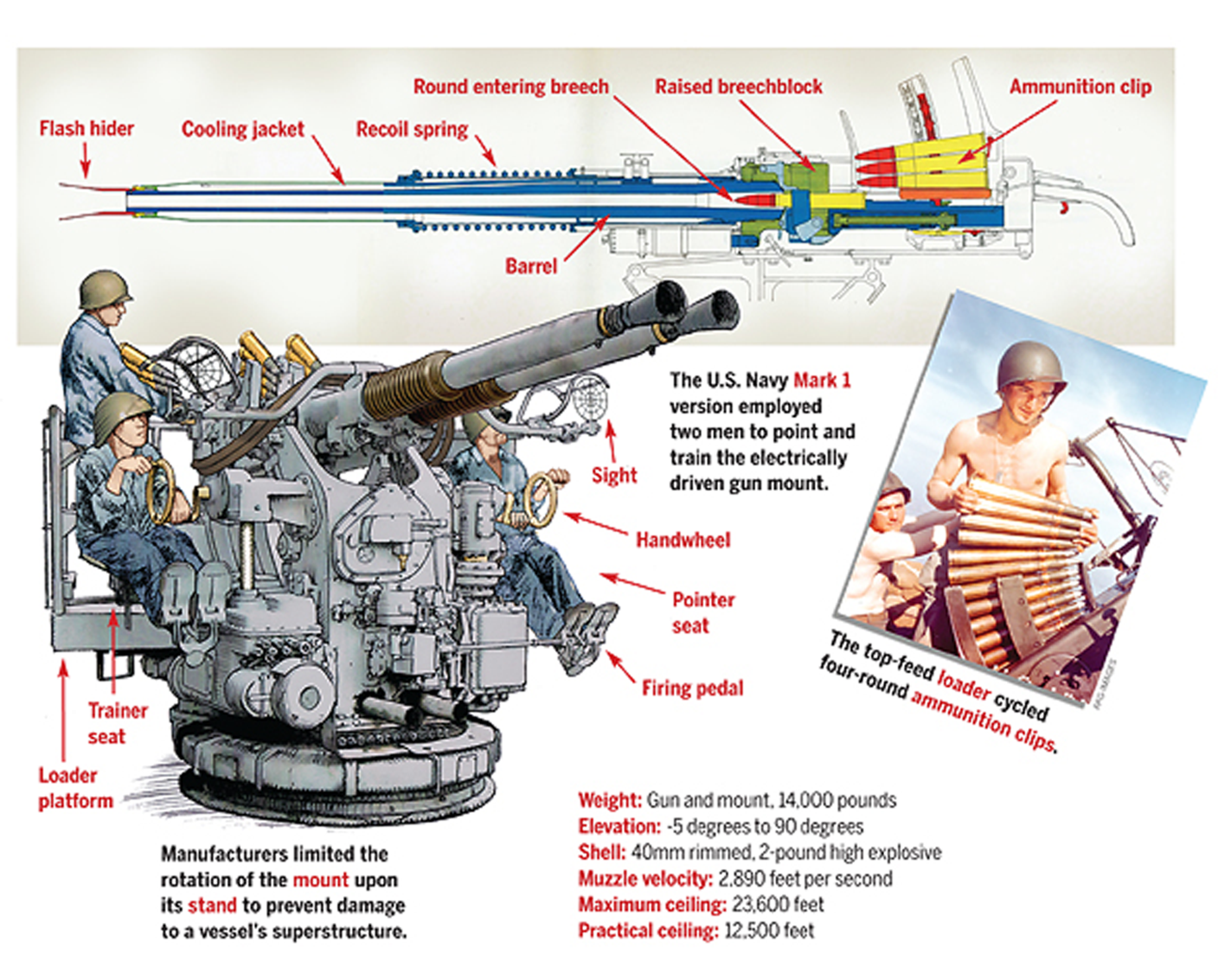

Probably the best automatic cannon anti-aircraft weapon of World War II, Bofors guns of this type remained in service long after the war ended. This weapon was used on almost every major USA and UK warship of World War II and was a very potent AA gun.

These guns are recoil operated and use a monobloc barrel with a detachable breech ring, breech casing and automatic loader. The barrel was attached to the breech ring via an interrupted screw design. The breech block was a vertical sliding type which was developed from the Finspong (Swedish arms manufacturer of the 1800s) 57mm Ssk M/89B. Although often listed as being 60 calibers long, all guns from all nations except Japan were actually 56.25 calibers in length.

Development by Bofors

This weapon traces its roots back to a 1918 Krupp design - the Bofors Company was partly owned by German interests until 1930 - but the finished product was entirely a Bofors design owing little or nothing to Krupp influence. During the late 1920s the Swedish Royal Navy approached Bofors a few times with requests to design a new 40 mm AA gun to replace the British 2-pdr. guns currently in service. Bofors showed little interest in this project as the size of any order from the Swedish Navy would be small and they did not see much possibility in foreign orders. However, the Navy persisted and finally offered to help fund the development costs. With this money in hand, Bofors started to actively work on a new AA weapon. The first Bofors test-bed prototype was finished late in the summer of 1930 and this fired three rounds using the automatic loader on 17 October 1930. Design and manufacturing of the first gun followed and single shots with it were fired on 10 November 1931. By 25 November 1931 trials had progressed to firing eight rounds in 7.58 seconds. This showed that the autoloader design concept would work, but more effort was needed before the prototype could meet the 130 rpm requirement. Official trials for the Swedish Navy took place successfully on 21 March 1932. This design was modified into a submarine gun and adopted by the Swedish Navy as the 40 mm L/43 Model 1932.

The basic design was further refined over the next two years, with 30,000 hours of drawing board work needed to produce 1,800 working drawings and 1,600 machine tool drawings that made up the improved 40 mm L/60 Model 1934. This model was exported to several countries but not adopted by the Swedish armed forces.

It was not until 1936 that the Swedish Army and Navy placed orders for a very slightly modified version and this became the 40 mm L/60 Model 1936 whose basic design was used for most guns produced during World War II by Bofors, the UK and the USA. Although the UK and USA halted production with the end of the war, Bofors continued to manufacture the 40 mm L/60 until 1954 when production was halted in order to concentrate on the more powerful 40 mm L/70 and 57 mm L/60 guns.

Click image below to zoom

USN Twin 40 mm Bofors Mount. Note the case discharge chutes at the right and the ejector chutes at the rear of the guns. These provided a safe path for expended cartridges off the mount at any angle of elevation.

Use by USA

The US Army was also interested in this weapon and tested a single air-cooled model in 1937. In 1940 the Chrysler Corporation agreed to begin manufacturing air-cooled guns utilizing British blueprints. The USN acquired many of these air-cooled guns during the war, although the quantity used was far less than that of the water-cooled guns.

The US Navy had a good deal of pre-war interest in this weapon and BuOrd purchased a sample of an air-cooled twin version from Bofors in early 1940. This arrived in New York from Sweden on 28 August 1940. During the same month, the Dutch escort vessel van Kinsbergen demonstrated these weapons to USN observers in a test off Trinidad. BuOrd formally obtained Swedish licenses in June 1941, although some manufacturing actually started prior to that time. Terms of the license included $500,000 for the manufacturing rights plus $100,000 for two Bofors engineers to help set up production. The two engineers were never sent, so as a result this $100,000 was not paid. Bofors delivered a complete set of metric drawings as part of their end of this contract.

It should be noted that the USN considered the original Bofors Model 1936 design to be completely unsuitable for the mass production techniques required for the vast number of guns needed to equip the ships of the US Navy. First, the Swedish guns were designed using metric measurement units, a system all but unknown in the USA at that time. Worse still, the dimensioning on the Swedish drawings often did not match the actual measurements taken of the weapons. Secondly, the Swedish guns required a great deal of hand work in order to make the finished weapon. For example, Swedish blueprints had many notes on them such as "file to fit at assembly" and "drill to fit at assembly," all of which took much production time in order to implement - there is a story that one USA production engineer remarked that the Bofors gun had been designed so as to eliminate the unemployment problems of the Great Depression. Third, the Swedish mountings were manually worked, while the USN required power-worked mountings in order to attain the fast elevation and training speeds necessary to engage modern aircraft. Fourth, the Swedish twin gun mounting supplied to the USA for evaluation was air-cooled, limiting its ability to fire long bursts, a necessity for most naval AA engagements. Finally, the USN rejected the Swedish ammunition design, as it was not boresafe, the fuze was found to be too sensitive for normal shipboard use and its overall design was determined to be unsuitable for mass production.

US manufacturers made radical changes to the Swedish design in order to minimize these problems and as a result the guns and mountings produced in the USA bore little resemblance their Swedish ancestors. For example, all but the earliest US guns were built to English measurement units rather than to metric units. To give one additional example of the design differences made for USA produced weapons; the Chrysler Corporation redesigned ten components to suit mass production techniques and this was claimed to have saved some 7,500,000 pounds (3,402,000 kg) of material and 1,896,750 man hours during a year's production, as well as freeing up 30 machine tools for the production of other components.

For ammunition, the fuze designed and produced in Britain was adopted as an interim measure by the USA, but this was considered to be of an unsafe design and unsuitable for mass production techniques. Fortunately, this fuze was almost immediately replaced by one designed by R.L. Graumann of the Naval Ordnance Laboratory. This fuze was simple in design and "ideally suited to mass production." The new fuze, designated as the Mark 27, was found to be 99.9 percent efficient in ballistic acceptance tests, a record not equaled by any other fuze of the time. Both the US Army and the British adopted this fuze for their own production lines. The USN estimated that the adoption of the Mark 27 saved some $250,000,000 during the war.

One firm rule adopted early in the redesign process was that any new Allied munition for these weapons needed to be completely interchangeable with existing designs. This allowed ammunition produced by any American or British ordnance manufacturer to be used with any weapon produced by either country, thus greatly simplifying the logistics problems of a world-wide war.

The first USN pilot twin was completed in January 1942 and the first quad in April 1942. The first shipboard quad installation was on the gunnery-training ship (ex-battleship) USS Wyoming (AG-17) on 22 June 1942, and the first twin installation was on the destroyer USS Coghlan (DD-606) on 1 July 1942. The USA started a massive production program for these weapons and a monthly production rate of 1,600 Army guns and 135 Navy twin-barrel guns was achieved by December 1942.

A note on sources: "The Bofors Gun" by Terry Gander says that the USA built total of about 42,895 guns by the end of the war, distributed as 23,897 for the Army, 10,019 for the Navy and Coast Guard, and 8,979 for export to other nations. However, these quantities do not agree with other sources, including the U.S. Navy publication "Bureau of Ordnance in World War II" which lists nearly 40,000 guns just for the Navy and Coast Guard (see USA Mountings below). According to this source, the 10,019 figure quoted by Gander seems to be the total of guns used in Navy single mountings, not the total number of guns used in all mounting types built for the USN. Whatever the correct figures, the needs of equipping Navy ships were not fully met until well into 1944. By that time, the pre-war 1.1" gun had been almost totally replaced by Bofors guns. To illustrate how many of these weapons were produced by the USA, note that out of the more than 400 destroyers built for the USN between 1934 and 1946, only the four destroyers of the pre-war Gridley class (DD-380) and those destroyers sunk early in the war did not receive at least some Bofors guns.

Late in World War II, the USN started replacing 20 mm Oerlikon guns with the Bofors 40 mm guns, as the smaller weapon was found to be ineffective against Japanese Kamikazes. However, even the Bofors was determined to be inadequate against suicide attacks by early 1945, and as a result a crash program was started late in the war to develop a new rapid fire 3"/50 (7.62 cm) gun to replace the Bofors. It should be noted that although the Bofors gun was probably the best anti-aircraft automatic cannon of World War II, the USN considered it to be a front-line weapon for only six years. It did remain in service in the USN until the 1970s on auxiliary and non-modernized ships, primarily because the 3"/50 RF (7.62 cm) replacement program was never fully funded.

Early versions of the Bofors twin mounting used friction-coupled drives, which quickly wore out on naval ships due to salt contamination. Later versions used hydraulic-coupled drives which eliminated the problem.

The development of the Mark 51 director system gave the USA weapons greatly improved accuracy. For example, half of all Japanese aircraft shot down between 1 October 1944 and 1 February 1945 were credited to the Bofors/Mark 51 combination. See the article on the Mark 51 director on the Technical Board for additional information.

The USN 40 mm/56 Mark 1 and 40 mm/56 Mark 2 Bofors guns were both water-cooled and were used for all twin and quad mountings. The Mark 1 was a left-hand weapon while the Mark 2 was a right-hand weapon. Except for the barrel assemblies, the components were not interchangeable. These weapons could be fired in single-shot or automatic mode via a selector switch on the side of the slide.

The 40 mm/56 M1 was an air-cooled version originally produced for the US Army. The barrel assemblies for the M1 were interchangeable with those of British and Canadian produced air-cooled weapons. All USN single mountings used a modified version of the Army M1.

Source: NavWeapons.com

Oerlikon 20mm Cannon

The Oerlikon [pronounced OR'-LA-CONN] 20mm anti-aircraft cannon was based on an original German 20mm Becker design that appeared very early in World War I. It was widely produced by Oerlikon Contraves and others, with various models employed by both Allied and Axis forces during World War II.

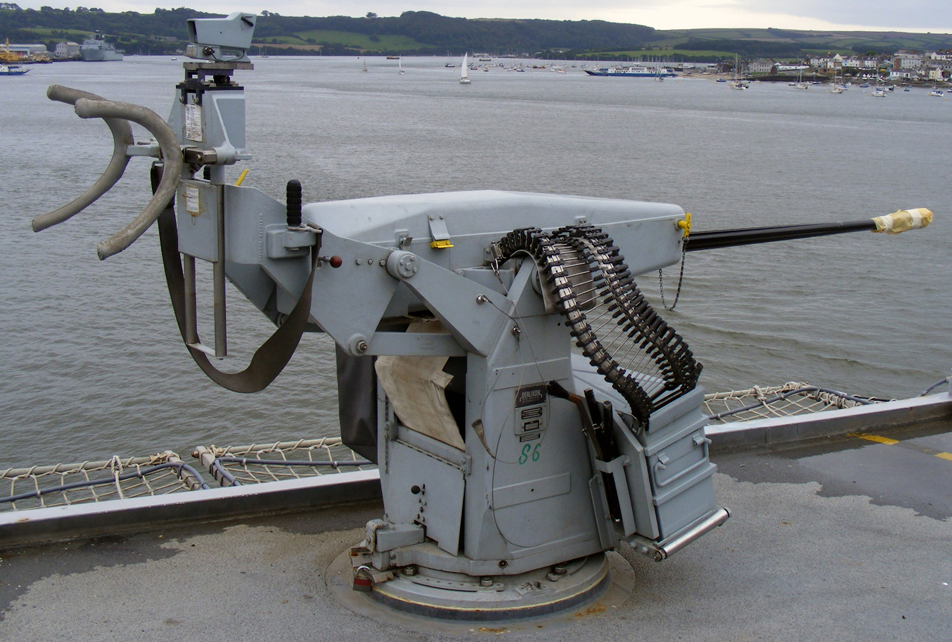

A modern Oerlikon cannon (Oerlikon 20mm/85 KAA) on a Royal Navy warship.

Side view of the Twin 20 mm Oerlikon anti-aircraft gun. In the background: destroyer HMCS Haida moored as museum ship at Hamilton, Ontario.

Rear view of the twin Oerlikon gun mount.

Preserved twin 20mm Ok guns on museum ship.

Source: guns.com

Origins

Back in 1918, German arms engineer Reinhold Becker came up with a 20x80mm round that fired using primer ignition blowback in a very large machine gun to fire at 300-rounds per minute. This gun was to be used to help sweep the sky of the Western Front of those pesky thousands of American, British, and French biplanes in the last year of World War 1. Too bad for Becker, (not to mention the Kaiser) the guns were never made in enough numbers to affect the war and his design was shelved.

In 1934 the Swiss based company of Oerlikon Contraves (Oerlikon being the name of the town the factory was located in and contra-aves being Latin for “against birds”) dusted off Becker’s design and super-sized it to be able to better shoot down the more modern fighters of the 1930s.

This gun, typically just referred to as the 20mm Oerlikon, became perhaps one of the most effective AAA (antiaircraft artillery) cannons of World War 2.

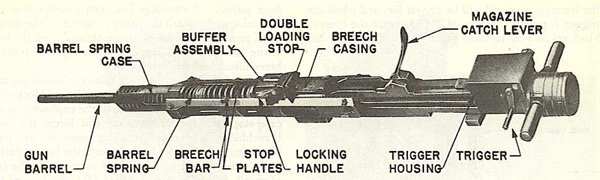

Design

Oerlikon Contraves took the design of the SEMAG; a larger version of Becker’s earlier gun chambered in 20x100RB and started a redesign. The final product used a simple blowback action, like the M1A1 Thompson and M3 Grease Gun to cycle. This required the use of a very heavy (to retard the recoil) open bolt without a locking lug as well as a huge spring (that weighed six pounds) that would push the bolt forward again after the round fired. This design cuts out gas impingement, piston rods, and even separate firing pins, creating a very simple action that is hard to break and what this meant was that the gun would run dirty, frozen, wet, unlubricated, full of blood, or encrusted with sea salt when others wouldn’t. Think of an all-steel 20mm Hi-Point Carbine that fired full auto from an open bolt and you have the basic design in mind.

In its final version, pitched in the late 1930s to the British and US Navies (as well as to the Germans and Japanese), the Oerlikon had been upgraded to the 20x110RB round at up to 450-rounds per minute. This huge 7-inch long, half-pound round used a 400-grain charge of IMR 4831 smokeless powder to propel a 2,000-grain projectile at 2,800 feet (850 meters) per second through a 55-inch long 9-groove barrel. For comparisons, this round is about three times as heavy as the .50 BMG round fired by the M2 heavy machine gun. Produced in no less than 11 different loadings it could reach out to one mile away.

These cannon were not what you could consider ‘portable’. Weighing in at nearly 150-pounds with rather serious recoil, the gun could not be carried by a light vehicle let alone a squad of soldiers. The main use was in mounting it to ships at sea for the purpose of stitching up surface targets like small boats and shooting down attacking aircraft. In a pinch, they could also be used to suppress fire ashore on the beaches if the ship was brought in close enough.

Use

The US Navy had just a few hundred of these guns on hand when the Japanese struck Pearl Harbor on December 7, 1941. Unlike many overseas made guns that used a belt, the US Navy’s model used a distinctive 60-round spring loaded drum magazine on the top of the gun. By distributing the plans and letting contracts go to numerous automobile manufacturers including Hudson and General Motors, more than 120,000 of the guns were made before the end of the war. Coupled with the MIT-designed electric Mark 14 electric gunsight that triangulated an aiming point on a rapidly approaching aircraft stabilized by two internal gyros, it was one of the most advanced weapons of its day.

The hardy 20mm Oerlikon was mounted on everything from tugboats and minesweepers to aircraft carriers. Usually manned by a five-man crew, it could be fired by a single sailor in a pinch—and often was. In post-war studies it was found that no less than one third of the Japanese aircraft shot down over the Pacific were down so by the German-invented, Swiss-perfected, US-built Oerlikon.

The gun was also well used by the British, Soviets, and numerous other nations during the war. The Japanese themselves even used the design (as the Type 99 auto-cannon), which led to something of a Twilight Zone scenario; while US Navy Oerlikon gunners were firing at Japanese A6M Zero fighter planes (that carried their own Oerlikons) Japanese Navy Oerlikon gunners were using their nearly identical gun to fire at US Navy planes.

Chicago Piano 1.1"/ 75 Caliber AA Gun

1.1" mount aboard USS Enterprise (CV-6), 1942.

During the 1930s, the U.S. Navy’s effort to design an anti-aircraft gun by committee resulted in the 1.1-inch quadruple anti-aircraft gun, affectionally known as the “Chicago piano.” By any standard, it was a dismal failure. The fact is, this piece of ordnance could not be phased out quickly enough on U.S. warships in favor of the far better 40mm Bofors guns.

The 1.1-inch/75 caliber gun mounts were over-weight, overheated easily and were subject to frequent breakdowns. As Bofors mounts replaced this infamous design in 1942, at first, only the highest value ships received the new guns. That usually meant carriers and battleships. Even the cruisers engaged in the night time knife fights around Guadalcanal had the 1.1-inch guns replaced by Bofors in penny-pinching packets. Some USN cruisers in that slugging match had combinations of 1.1-inch guns and Bofors fitted at the end of 1942. It you were on a destroyer or something smaller, that had the heavy 1.1-inch mount, it was "Don't hold your breath!" on the question of replacing this lemon with the magnificent Bofors guns.

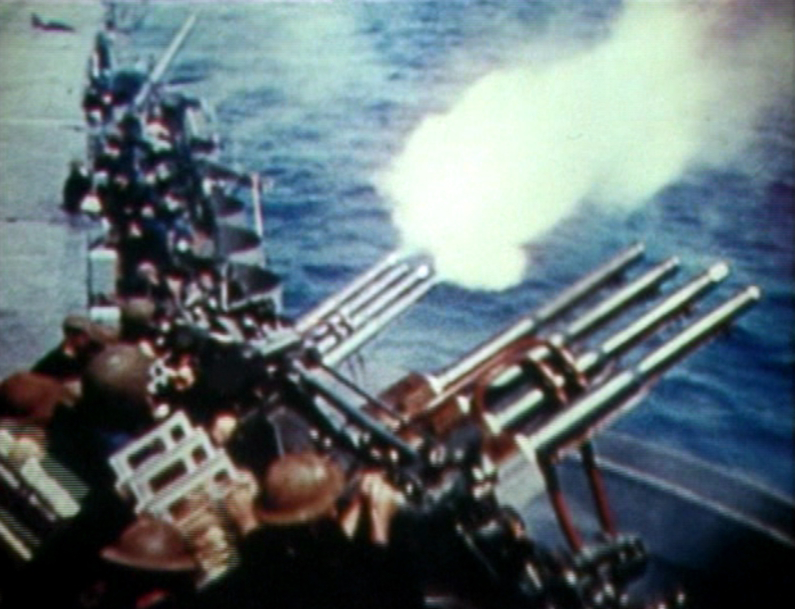

1.1" mounts firing aboard USS Hornet (CV-8), May 1942.

While 1.1-inch guns rendered valuable service in early Pacific battles, 40-mm Bofors replaced them in most Navy warships. Destroyer escorts, primarily used to hunt down submarines–not guard against air attack–continued to make due with 1.1 guns, including these on board the USS Francis M. Robinson (DE-220).

History

The 1.1"/75 caliber gun was an American anti-aircraft weapon of World War II, used by the United States Navy. The name means that it had a bore diameter of 1.1 inches (28mm) and barrel length of 75 x 1.1 inches = 82.5 inches (2.1m), using the "caliber" nomenclature common to large artillery pieces. The gun was designed to replace the M2 Browning and four barrels were required to duplicate the rate of fire. The first shipboard installation in 1939 was quickly nicknamed the “Chicago Piano”, possibly because it was the size of a baby grand piano and looked a little like a baby grand without its lid. Although the reminiscences of the sailors who served with these guns all agree on the nickname, no one seems to know where it originated.

By 1941, these guns had been mounted on destroyers, cruisers, battleships, aircraft carriers, and some auxiliary ships. Nearly a thousand guns had been produced before production shifted to more reliable shipboard anti-aircraft machine guns in 1942. Quantities were minimal; one mount for a destroyer, two mounts for pre-1930s battleships, and four mounts for North Carolina–class and newer battleships. On at least some ships they were director-controlled.

The gun was very unpopular with its crews; it was said that due to its tendency to jam, the only way to fire one was to position a gunner's mate on his back underneath the mount, equipped with an assortment of wrenches and hammers to clear them. It was replaced by Oerlikon 20mm cannon or Bofors 40mm guns whenever possible, but served until the end of the war on some ships. A twin Bofors gun was about the same weight, and was a much more powerful gun. The air-cooled Oerlikon had similar effective range and rate of fire with considerably less weight. The Oerlikon could not sustain fire for as long as the water-cooled 1.1", but six Oerlikons could be installed for the weight of a single 1.1" quad mount.

Regardless of these problems, the 1.1-inch guns were a welcome addition to the Fleet’s antiaircraft defenses and played an important role in protecting U.S. carriers at the battles of the Coral Sea and Midway.

Source: Wikipedia

Weapons Videos

The 20mm Oerlikon Anti-Aircraft Cannon [7:00]

The 20mm Oerlikon automatic cannon was a mainstay of United States naval air defense during World War 2, and today we will look at a few of the characteristics and questions that apply to this sort of automatic cannon but not to typical small arms. Like, for instance, how do you cock a gun that has a 400 pound recoil spring? Or, what happens if you fire a high explosive shell into your muzzle cover?

ForgottenWeapons.com does a very interesting and comfortable approach to this classic military weapon. Watch Four Fun Facts about the Oerlikon 20mm Antiaircraft Cannon.

Shooting the 20mm Oerlikon Gun [0:57]

You can watch hours of video clips on the history of various weapon systems but there is noting more satisfying that actually seeing a weapon in operation. In other words, here is a minute of fun watching the legendary 20mm Oerlikon cannon being fired. Enjoy!

Naval Legends: Oerlikon 20mm Gun [10:37]

This is one of the World of Warships Naval Legends series. It is about the Oerlikon 20mm anti-aircraft gun. This series is incredibly well-done. Recommended!

Naval Legends: Bofors 40mm Anti-Aircraft Gun [12:55]

The Bofors 40mm gun was a truly global weapon. The Swedish Bofors L60 has served as the antiaircraft gun of choice for countless nations. This is another one of the World of Warships Naval Legends series. This series is incredibly well-done.

Bofors 40mm Anti-Aircraft Gun [13:50]

The Swedish Antiaircraft / Artillery Bofors 40mm Automatic Gun M1 was simply the best anti-aircraft gun in the U.S. Navy's inventory during WWII. ForgottenWeapons.com is back with another interesting video on a classic military weapon.

The Bofors Gun [8:15]

The Bofors 40mm, often referred to simply as the Bofors Gun, is an anti-aircraft/multi-purpose autocannon designed in the 1930s by the Swedish arms manufacturer AB Bofors. But by 1943, the Bofors made in the US by Chrysler and about 50 subcontractors had very little relation to the original Swedish gun of 1939. It took Chrysler six months working 24 hours a day to convert the blueprints from metric to imperial and fabricate about 2,000 replacement parts that were suitable for mass production and interchangeable. The ammunition needed to be reworked with new fuses because the USN considered the Swedish specified ammunition as not being bore safe, therefore dangerous. Chrysler and the Navy were able to build hydraulic systems into completely new mounts for the twin and quad Bofors. It was clear to the Navy that air cooled barrels, while fine for the Army, would never work on ships firing these firing for periods up to an hour straight. Once again, Chrysler and several subcontractors developed a water jacket cooling system in less than six months. Work first started in June, 1941, and the twin pilot model was ready by January, 1942 and the quad by April, 1942. It was an industrial effort rarely met and never surpassed. The addition of the Mark 51 gun fire control system later in the war greatly increased the number of hits per 100 rounds and made the quad 40 mm and the 5"/38 the two guns that saved the fleet against the kamikaze onslaught.

5 Inch 38 Caliber Anti-Aircraft Guns [32:42]

This video is part of the archive used by docents on the USS Hornet museum for training purposes. The USS Hornet Museum is a museum ship in Alameda, California, US. It is composed of the aircraft carrier USS Hornet, exhibits from the NASA Apollo moon exploration missions, and several retired aircraft from the Second World War and the transonic and early supersonic jet propulsion period.